La maintenance of water supply systems is a fundamental element in ensuring the safety and quality of a basic commodity that we consume on a daily basis. We at DKR, active since 1983 in the construction and maintenance of office water dispensers, schools e Horeca sectorwe know that this aspect cannot be neglected. Since 1996 we have been realising Water Houses and we also take care of their revamping, as was the case for those installed at Expo 2015. This experience has taught us how crucial it is to maintain high standards of maintenance to ensure the longevity and efficiency of the systems.

Any dispensing system that provides a filtration treatmentor even cooling alone, changes the characteristics of the drinking water supplied by the waterworks. This is why it must be subjected to strict controls and periodic checks. Water is a foodstuff and its modification must not be dangerous for the user who drinks it. In particular, regulations require that the modification does not worsen the quality of water for food use.

This is why the control and prevention system for food processing chains was created, whereby the risks in terms of bacteriological pollution, contamination and critical points of each process are thought out and studied. This is why every operator who is in contact with food and foodstuffs and works with them must have done an HACCP course.

The Italian regulatory framework has established precise guidelines for the management of water supply systems. The Legislative Decree 18 of 23 February 2023 is the main reference point, classifying installations into different categories according to their level of risk and environment of use.

The regulations identify the most critical environments and divide them into categories, starting with the most critical:

The categories we are most interested in are the last two. The first is subject to food jurisdiction, the treatment process is subject to HACCP (Hazard Analysis and Critical Control Points). In HACCP protocol a natural person or company, who assumes the role of FBO (Food Business Operator), must be indicated as the person responsible for verification and quality.

The second category is subject to the food safetywhich in each case involves checks on the installation, maintenance and analyses to verify that the result of the operation of the installation is protective of the health of those using it.

When talking about water, one often hears the argument that water is the source of life, or that life originates from water, or that there can be no life on a planet without water. These sentences highlight how important water is for human life, but in detail they also point out that water, if not subjected to proper treatment, changes quickly, creating bacteria, moulds, fungi and many other forms of life.

Aqueduct water counteracts these formations with a careful choice of sources orwhere this is not possible, with purification systems first and bacterial proliferation control later. Chlorine and other antibacterial substances are introduced into the water supply to keep the water safe during transport.

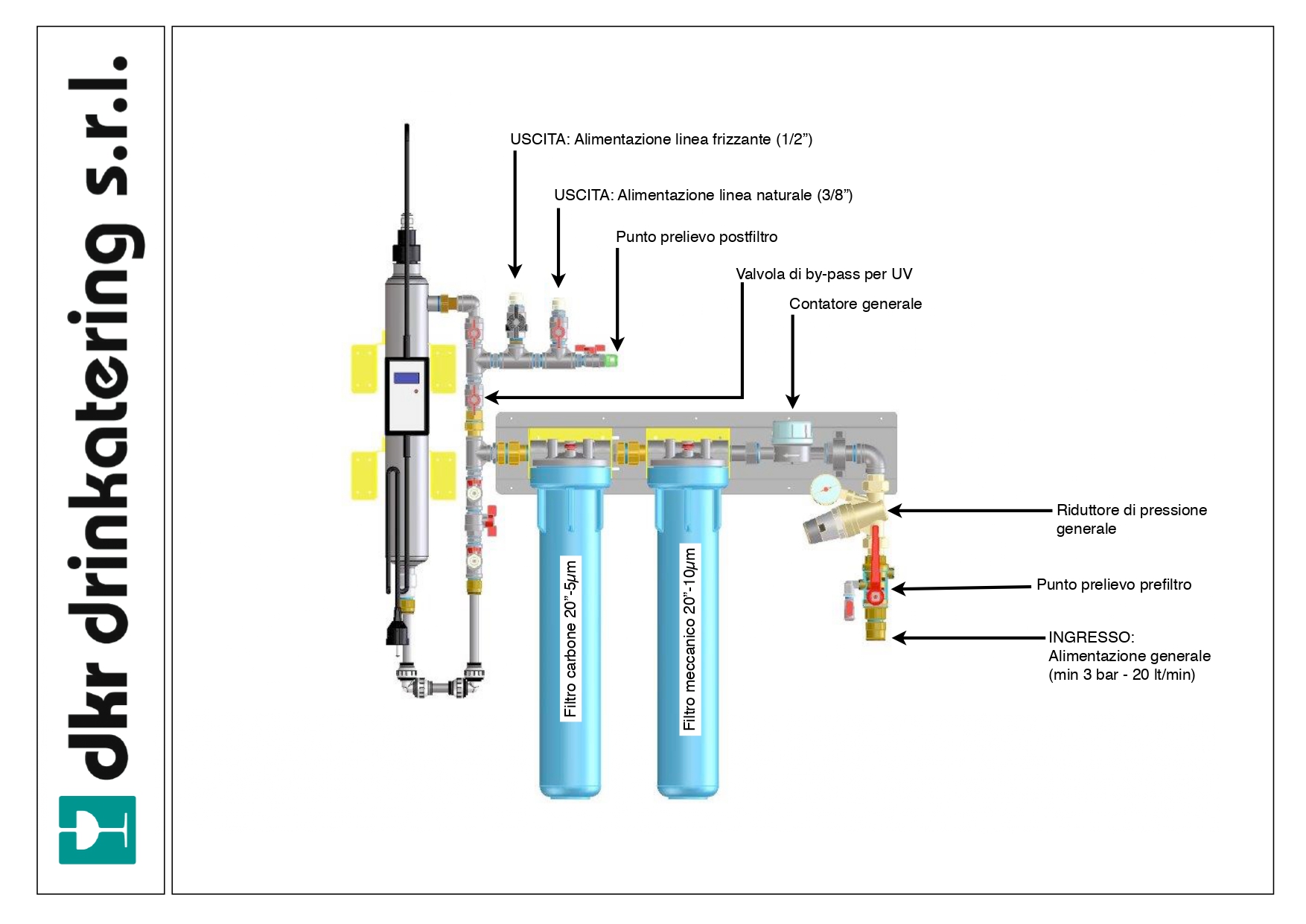

In point-of-use water irrigation systems - be they dispensers in companies or schools, or Water Houses in public squares - filtration organoleptically alters the qualities of the water dispensed, removing flavours, odours and chemicals including chlorine.

The filter, coils and delivery point are in continuous contact with water. Water, as we said before, if not covered with an antibacterial, can easily change. Stagnation, heat, poor hygiene can facilitate the spread and proliferation of bacteria.

La maintenancecarried out regularly by qualified personnel, ensures that an environment favourable to bacteria is not created. Pipes, taps, fittings are cleaned with special material that is inserted into the system and left in contact for the necessary time.

Filters must also be replaced, which can become saturated if they are not changed. A saturated filter no longer does its job, but rather becomes a source of bacterial proliferation.

Particular attention must be paid to the ultraviolet lamp, which acts as a bactericide in a system. To function properly, it must ensure adequate contact between the water and the UV rays it produces and irradiates. For this it must be cleaned at least every 6 months and replaced once a year.

To verify that everything has been done correctly, it is good practice to take a sample and perform a bacteriological analysis at an authorised laboratory, certifying the goodness of the work.

In working environments without food production, we recommend:

Le bacteriological analyses are compulsory in all cases. This is not only to comply with regulations, but above all to ensure the safety of those who use our facilities.

We hope that with these few lines you have understood that behind a dispenser that dispenses pleasant, safe and fresh water, there is attention to every detail, years of experience and work, many problems solved that have produced an experience available to the end customer.

Our 40 years in the industry have taught us that the world of water is complex and requires specific skills. When you are offered a system, in addition to seeing whether you like it and whether it fits well into your environment, pay particular attention to the quality of the company you are approaching.

At DKR, we provide our customers not only with high-quality installations, but with a comprehensive service that includes:

Each intervention is documented and trackedproviding our customers with the peace of mind of always having

under control of the status of their plant. Our experience in the revamping of the Expo 2015 Water Houses has allowed us to further refine our skills in managing complex, high-utilisation plants.

Our long experience in the industry allows us to:

Contact us today for a free maintenance consultation on your water supply system. Our technicians are at your disposal to assess your specific needs and propose a customised maintenance plan. The health of your employees and customers deserves only the best.